|

Listen to this article

|

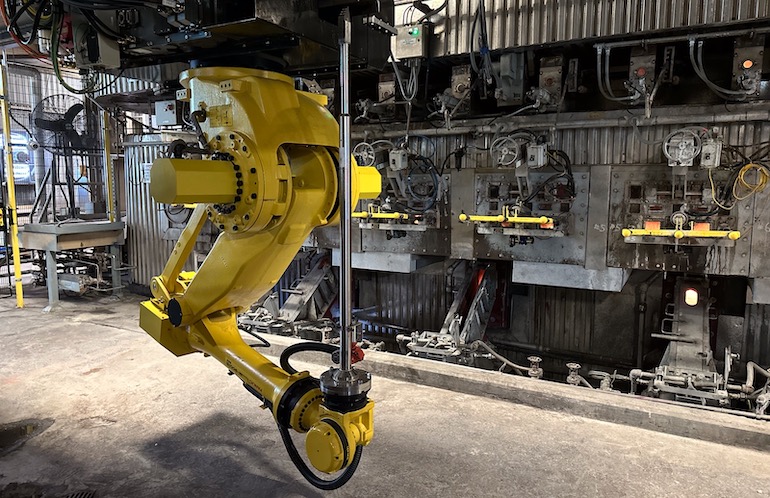

North American paper mills are starting to use robotics for smelt spout cleaning. Source: Valmet

Recovery boilers represent a significant capital expenditure in the pulp and paper industry. While a well-maintained boiler can last for decades, routine care of this system can present challenges. Maintenance duties are often messy and risky for the operator, and many tasks are time-consuming and require full or partial boiler shutdown. This can harm overall productivity and mill safety.

One maintenance task that is particularly challenging in the care of recovery boilers is smelt spout cleaning. While cleaning smelt spouts is essential for efficient recovery boiler performance, it can pose serious safety risks to the operator when the spouts are cleaned manually.

These risks include the operator encountering molten smelt, green liquor, and hot gasses, as well as repetitive-motion back and shoulder injuries. Finding operators who are willing to perform these tasks, training them, and retaining them over time have also become part of the challenge.

To improve operator safety during smelt spout cleaning and increase both operator and boiler productivity, pulp and paper facilities now have automated robotic solutions that can take on these more difficult tasks.

Robotic technology for smelt spout cleaning has been available since 2008, but it has only recently entered North American paper mills. Its delayed entry has been largely due to low numbers of new recovery boiler installations, as the robot requires a certain amount of space that is often difficult to allocate within existing operations.

Now, as North American operations are in greater need of the benefits that accompany smelt spout cleaning robots, they can invest in retrofitting existing recovery boilers with robotic solutions.

Smart design removes barriers to robotics retrofits

For pulping operations, one of the biggest barriers to adopting a smelt spout cleaning robot is often the amount of space that’s required for the robot to move around the spout deck during the cleaning cycle. In many facilities, this area around the smelt spout systems is already tight, which is part of what makes manual smelt spout cleaning difficult and risky for operators.

As automation designers have continued to invest in understanding the safety and productivity challenges faced by the pulp and paper industry, new solutions have emerged that remove this common barrier to adding robotics.

For instance, one smelt spout cleaning robot offers the option of a standing mount or a hanging mount. All that’s required to employ the hanging mount and position the robot next to the recovery boiler is a linear rail assembly.

The assembly allows the robot to move side-to-side along the spout deck to clean all spouts. Then, it moves off the spout deck once it completes the cleaning cycle. This configuration maintains sufficient room for the robot to perform its tasks while also ensuring that operators can safely enter the area to perform other duties.

Protective fencing and multiple entry and exit points will also be incorporated for additional operator safety and efficiency. The majority of retrofit work can typically be completed pre-outage, leaving sufficient time during the maintenance outage for robot installation and commissioning.

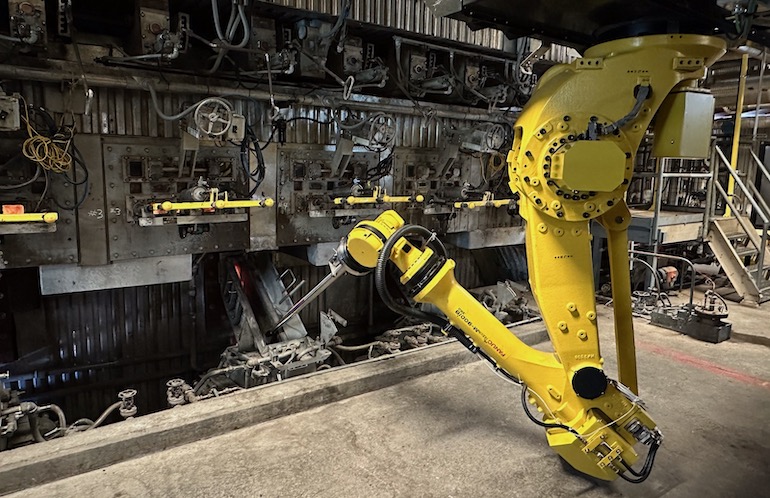

Robots can relieve worker strain but require careful integration and deployment. Source: Valmet

Smelt spout-cleaning robots proven in the field

In June 2023, Valmet installed its first smelt spout-cleaning robot in North America at the Pixelle Specialty Solutions mill in Spring Grove, Penn. The new robot performs a smelt spout cleaning cycle every 30 minutes — twice as often as operators were previously able to perform the same task manually. Each cycle takes 15 minutes, and when the robot is not actively cleaning, it rests in its home position safely out of the way.

Physical safety barriers around the robot further protect the operators by triggering the robot to freeze if the barrier is broken. Operators can also remotely control the robot’s cleaning frequency and cycles using pre-programmed sequences. Meanwhile, an onboard camera mounted on the robot wrist allows for real-time inspection of the robot’s performance and troubleshooting from the safety of the control room.

By automating smelt spout cleaning with a robot, the manufacturer added another level of safety for its operators and improved productivity by freeing them up to perform other critical tasks. Additionally, the new robot has helped raise the boiler’s liquor quality, green-to-black liquor standard deviation, and smelt standard deviation by double digits.

Collaboration is key

When retrofitting a smelt spout robot to an existing recovery boiler or planning a new installation, it’s important to choose an automation designer that has industry experience and will collaborate on-site during the design phase.

Since every operation and facility is different, the installation of a smelt spout cleaning robot is not a cookie-cutter process. The designer will have to account for existing components around the spouts like piping, flex hoses and evaluate available structural beams for their ability to support the robot carriage and the linear rail.

A skilled designer will also provide an installation plan that avoids significant spout deck alterations, as changes can be costly and time-consuming.

Smelt spout cleaning robots are meant to work with operators, not replace them. Source: Valmet.

Technology works in harmony with humans

Automation often comes with the assumption of replacing human labor, but that is not the case with smelt spout cleaning robots. Instead, this technology works in harmony with boiler operators to increase their safety. It also frees them up to perform other essential recovery boiler tasks.

Helping operators feel safer and engaging them in a wider variety of tasks throughout their workday can make it easier for pulp and paper manufacturers to hire and retain personnel in these positions. With the efficiencies of automation and well-trained, experienced personnel, manufacturers can improve productivity in many areas, making robotics retrofits worth the investment.

About the author

About the author

Dan Morrison is Valmet’s product manager for Smelt Spout Systems and the Smelt Spout Cleaning Robot. The Espoo, Finland-based company is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries.

Valmet and Körber recently established a joint venture to connect the FactoryPal platform with machinery expertise to streamline digital optimization across the production lines of tissue shop floors and beyond.

Tell Us What You Think!