|

Listen to this article

|

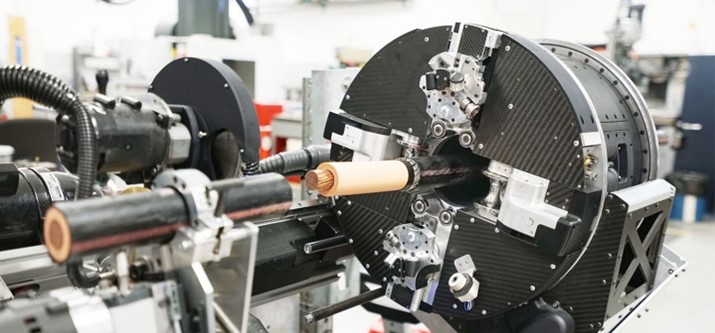

Above: Autonomous construction robot brings the accuracy of robotics to highly complex utility construction sites; The Robotic Roadworks and Excavation System is a 2021 RBR50 Award Winner

By Ali Asmari, Director of Project Management, ULC Technologies

In recent years, the market for field-deployed robotics has seen significant growth, mainly due to the advances in sensor technology, processing capabilities, and hardware efficiency. These technological advancements make it increasingly feasible and meaningful to develop robotic solutions for automating repetitive day-to-day tasks. The energy industry stands to benefit immensely from these innovations. Much of the repair and maintenance operations within this sector are currently performed by human operators, often exposing them to hazardous environments. By harnessing the power of AI and robotics, we can develop tools that enable these tasks to be carried out more safely and efficiently. This shift not only promises to enhance the safety and well-being of workers but also aims to improve operational efficiency and reliability in energy infrastructure maintenance and repair.

Who are you and what do you do?

ULC Technologies is a leader in the development and deployment of innovative robotic solutions and technologies for the utility, energy, and industrial sectors. We specialize in creating advanced robotic systems, AI-driven solutions, and smart inspection technologies designed to enhance operational efficiency, reduce environmental impact, and minimize disruptions to the public. Our extensive range of products includes solutions for pipeline inspection, infrastructure automation, and utility management, which improve safety and reliability in operations while confronting modern industry challenges. This includes the development of power line crawling robots to delivering an autonomous construction robot to one of our utility industry partners.

A typical robotics engineering company typically just builds the robots. Why does a robotics company need a field services division?

ULC Technologies recognizes the specialized nature of robotic operations, which often require highly trained operators with specific safety and operational training. Our field services division is essential because many of our innovative robotic solutions demand expert handling that our clients may not be equipped to manage. This division allows us to maintain a fleet of robotic platforms and employ skilled operators who can deploy these technologies effectively in the field, providing a full-service solution to our customers who prefer not to own and manage such assets themselves. However, for clients interested in owning the robotic platforms, we also offer services to build these robots and train their personnel, ensuring they are fully equipped to serve their specific industry needs. This dual approach allows us to cater to a wide range of customer needs, enhancing the accessibility and effectiveness of our robotic solutions in the field.

Above: ULC’s fleet of CISBOT robots work under the streets of New York City, Boston, London and other areas to remotely seal leak-prone pipe.

Over the last few years, ULC Technologies has really broken out of the pipeline market. What are some of the other challenges your teams are working on?

Our team has indeed expanded beyond our foundational pipeline market, although we continue to maintain a robust presence in that area with services that inspect and remediate underground gas assets. We have increasingly collaborated with numerous customers to develop solutions targeted at the energy sector, particularly to support the expansion and development of renewable energy sources. This strategic shift has been driven largely by initiatives from both the public and private sectors aimed at accelerating the expansion of the electric grid and integrating more renewable energy resources. These efforts align with global trends towards sustainable energy solutions and reflect our commitment to innovation in support of a greener future. We call it responsible innovation.

Prototype power line traversing robot developed for Meta

Machine developed for Con Edison to automate repair operations on medium voltage electric cables.

How does ULC Technologies ensure a smooth transition between a prototype and commercial robotic solution?

At ULC Technologies, the transition from prototype to commercial robotic solution is managed through strategic partnerships with both private and public sector companies within the industry. Throughout the development process, we engage these partners and their subject matter experts to ensure that our solutions align with existing industry standards and processes. This collaborative approach guarantees that, once a proof of concept is developed and validated in the field, scaling up for commercial rollout is a seamless process.

For companies looking to begin developing bespoke robotic systems, what advice do you want to share?

For companies venturing into the development of bespoke robotic systems, the pivotal piece of advice from ULC Technologies centers on the importance of thoroughly understanding the problem statement. Before diving into a complete development project with your robotics partner, it’s crucial to define and comprehend the specific problem that needs addressing. At ULC Technologies, we prioritize working closely with our customers to define the problem statement and assess the feasibility of a robotic solution. This foundational step ensures that the development efforts are precisely targeted and that the resultant robotic systems are highly effective and tailored to the unique needs and challenges of our clients. It’s this strategic approach that sets the stage for successful and impactful robotic solutions.

About ULC Technologies:

ULC Technologies partners with leading companies in the construction, energy, and industrial sectors to develop bespoke field-deployed technologies ranging from robotic systems, autonomous technologies, remote inspection solutions, and machine learning. Learn more at https://ulctechnologies.com/partner-in-innovation/

Sponsored content by ULC Technologies

Companies like ULC Technologies are filling in the gap in real life use case applications and building deep rooted relationships with B2B clients. I think that’s the right way to go.