|

Listen to this article

|

Zebra’s portfolio includes FlexShelf robots for parts fulfillment. Source: Zebra Technologies

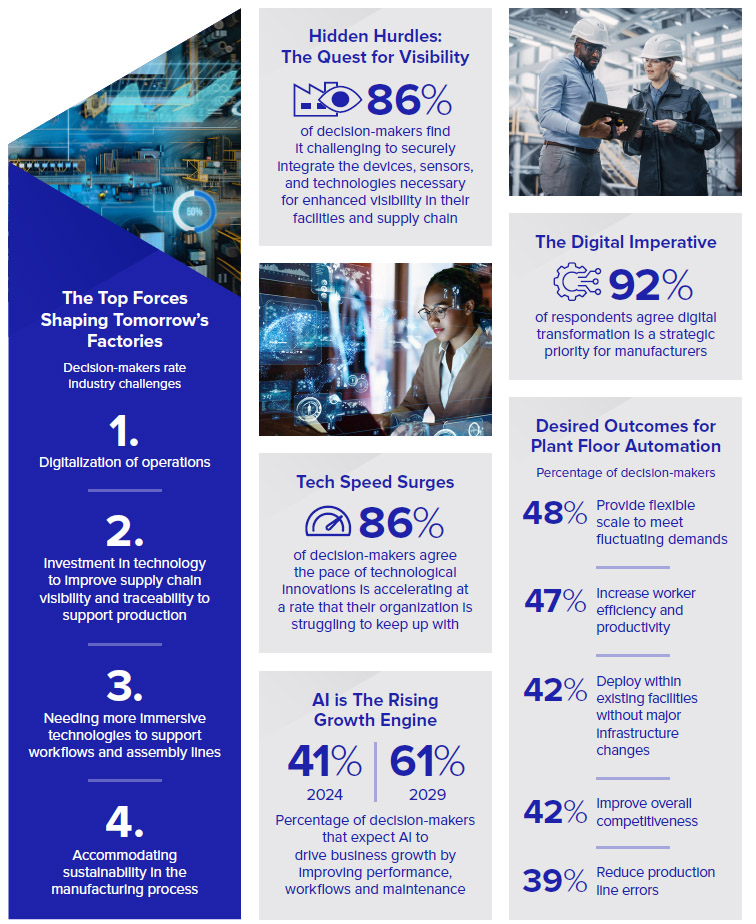

Only 1 in 6 manufacturers has a clear understanding of its own processes, according to a new study from Zebra Technologies Corp. The report also found that 61% of manufacturers expect artificial intelligence to drive growth by 2029, up from 41% in 2024.

Zebra said the surge in AI interest, along with 92% of survey respondents prioritizing digital transformation, demonstrates manufacturers’ intent to improve data management and use new technologies that enhance visibility and quality throughout production.

“Manufacturers struggle with using their data effectively, so they recognize they must adopt AI and other digital technology solutions to create an agile, efficient manufacturing environment,” stated Enrique Herrera, industry principal for manufacturing at Zebra Technologies. “Zebra helps manufacturers work with technology in new ways to automate and augment workflows to achieve a well-connected plant floor where people and technology collaborate at scale.”

Zebra commissioned Azure Knowledge Corp. to conduct 1,200 online surveys among C-suite executives and IT and OT (information and operational technology) leaders within various manufacturing sectors. They included automotive, electronics, food and beverage, pharmaceuticals, and medical devices. Respondents were surveyed in Asia, Europe, Latin America, and North America.

The fully connected factory is elusive

Although manufacturers said digital transformation is a strategic priority, achieving a fully connected factory remains elusive, noted Zebra Technologies. The company asserted that visibility is key to optimizing efficiency, productivity, and quality on the plant floor.

However, only 16% of manufacturing leaders globally reported they have real-time, work-in-progress (WIP) monitoring across the entire manufacturing process, reported the 2024 Manufacturing Vision Study.

While nearly six in 10 manufacturing leaders said they expect to increase visibility across production and throughout the supply chain by 2029, one-third said getting IT and OT to agree on where to invest is a key barrier to digital transformation.

In addition, 86% of manufacturing leaders acknowledged that they are struggling to keep up with the pace of technological innovation and to securely integrate devices, sensors, and technologies throughout their facilities and supply chain. Zebra claimed that enterprises can use its systems for higher levels of security and manageability, as well as new analytics to elevate business performance.

Technology can augment workforce efficiency

Manufacturers are shifting their growth strategies by integrating and augmenting workers with AI and other technologies over the next five years, found Zebra’s study. Nearly three-quarters (73%) said they plan to reskill labor for data and technology usage, and seven in 10 said they expect to augment workers with mobility-enabling technology.

Manufacturers are implementing tools including tablets (51%), mobile computers (55%), and workforce management software (56%). In addition, 61% of manufacturing leaders said they plan to deploy wearable mobile computers.

Across the C-suite, IT, and OT understand how labor initiatives must extend beyond improving worker efficiency and productivity with technology. Six in 10 leaders ranked ongoing development, retraining/upskilling, and career path development to attract future talent as high priorities for their organizations.

Automation advances to optimize quality

The quest for quality has intensified as manufacturers across segments must do more with fewer resources. According to Zebra and Azure’s survey, global manufacturers said today’s most significant quality management issues are real-time visibility (33%), keeping up with new standards and regulations (29%), integrating data (27%), and maintaining traceability (27%).

Technology implementation plans are addressing these challenges. Over the next five years, many executives said they plan to implement robotics (65%), machine vision (66%), radio frequency identification (RFID; 66%), and fixed industrial scanners (57%).

Most survey respondents agreed that these automation decisions are driven by factors including the need to provide the workforce with high-value tasks (70%), meet service-level agreements (SLAs; 69%), and add more flexibility to their plant floors (64%).

Zebra Technologies shares regional findings

- Asia-Pacific (APAC): While only 30% of manufacturing leaders said they use machine vision across the plant floor in APAC, 67% are implementing or planning to deploy this technology within the next five years.

- Europe, the Middle East, and Africa (EMEA): In Europe, reskilling labor to enhance data and technology usage skills was the top-ranked workforce strategy for manufacturing leaders to drive growth today (46%) and in five years (71%).

- Latin America (LATAM): While only 24% of manufacturing leaders rely on track and trace technology in LATAM, 74% are implementing or plan to implement the technology in the next five years.

- North America: In this region, 68% of manufacturing leaders ranked deploying workforce development programs as their most important labor initiative.

The Manufacturing Vision Study provided insights around digitalization and the connected factory. Source: Zebra Technologies

Zebra to discuss digital transformation

While digital transformation is a priority for manufacturers, achieving it is fraught with obstacles, including the cost and availability of labor, scaling technology solutions, and the convergence of IT and OT, according to Zebra Technologies. The Lincolnshire, Ill.-based company said visibility is the first step to such transformation.

Emerging technologies such as robotics and AI enable manufacturers to use data to identify, react, and prioritize problems and projects so they can deliver incremental efficiencies that yield the greatest benefits, Zebra said. The company said it provides systems to enable businesses to intelligently connect data, assets, and people.

Zebra added that its portfolio, which includes software, mobile robots, machine vision, automation, and digital decisioning, can help boost visibility, optimize quality, and augment workforces. It has more than 50 years of experience in scanning, track-and-trace, and mobile computing systems.

The company has more than 10,000 partners across over 100 countries, as well as 80% of the Fortune 500 as customers. Zebra is hosting a webinar today about how to overcome top challenges to digitalization and automation.

Tell Us What You Think!