|

Listen to this article

|

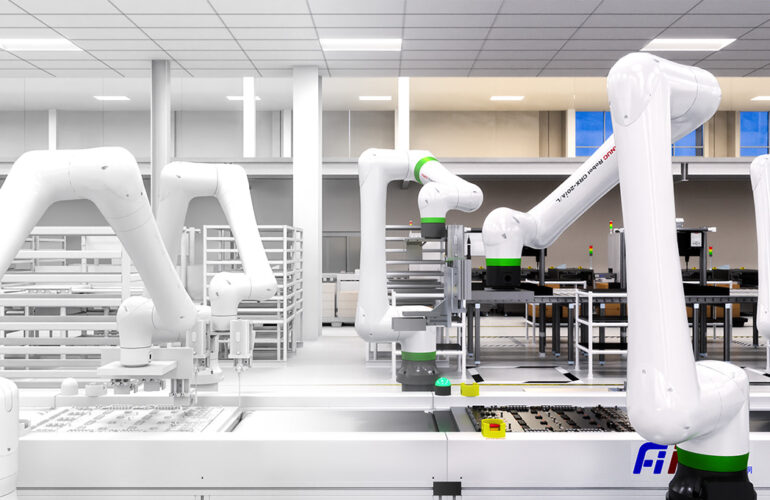

The NVIDIA Isaac platform powers electronics, healthcare and industrial applications. | Credit: eCential Robotics (left), Amazon Robotics (right)

In addition to artificial intelligence products, NVIDIA Corp. founder and CEO Jensen Huang announced several robotics-related items during his keynote today at COMPUTEX in Taiwan. The company said that many computer manufacturers are producing a new generation of “AI computers” using its chips to enable Omniverse for modeling and business workflows.

Back in April, NVIDIA announced several new robotics-related technologies at the 2024 GPU Technology Conference (GTC). These new products included Project GR00T, Jetson Thor, Isaac Lab, OSMO, Isaac Manipulator, and Isaac Perceptor.

NVIDIA Isaac Perceptor is a new reference workflow for autonomous mobile robots (AMRs) and automated guided vehicles (AGVs). Isaac Manipulator offers new foundation models and a reference workflow for industrial robotic arms.

The company has also updated Jetson for Robotics in NVIDIA JetPack 6.0. It has included NVIDIA Isaac Lab, a lightweight app for robot learning, in NVIDIA Isaac Sim 4.0.

The Santa Clara, Calif.-based company was also a 2024 RBR50 award winner for its Nova Carter reference AMR platform developed with Segway Robotics.

Manufacturers can simulate in Omniverse

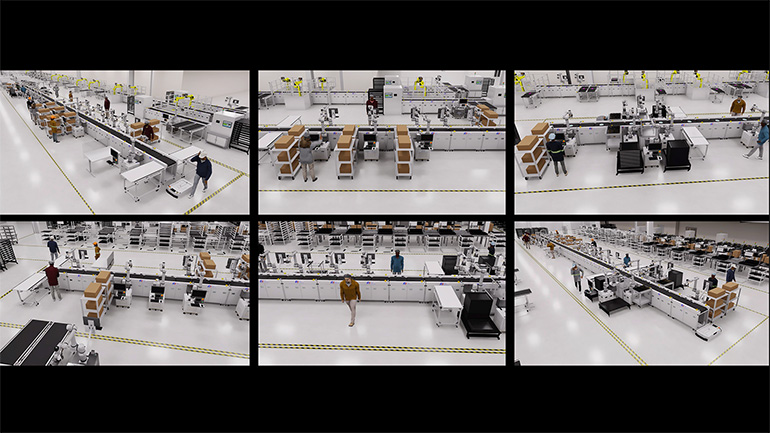

While there weren’t any new robotics product announcements, NVIDIA did say that many of its partners are beginning to use AI and Isaac SIM in the design of new manufacturing facilities. Through the creation of a digital twin of the factory floor, these companies are now able to simulate the assembly process by programming and running robots in simulation.

“Everything is going to be robotic. All of the factories will be robotic. The factories will orchestrate robots,” said Huang, reported Digitimes Asia. “And those robots will be building products that are robotic robots interacting with robots, building robotic products.”

He showed video clips that robots are all moving by themselves in the Omniverse, where simulations were implemented through digital twins.

“Generative physical AI can learn skills using reinforcement learning from physics feedback in a simulated world,” Huang said during his keynote. “In these simulation environments, robots learn to make decisions by performing actions in a virtual world that obeys the laws of physics.”

Taiwanese chip manufacturer and NVIDIA partner Foxconn is using Isaac SIM to plan factories that will produce the next generation of NVIDIA processors.

NVIDIA also announced that electronics manufacturers Delta Electronics, Pegatron, and Wistron are using NVIDIA Metropolis, Omniverse, and Isaac to simulate, build, and operate their facilities with “virtual factories.”

Foxconn’s factory simulated in Omniverse, featuring AI robots developed by NVIDIA robotics partners. | Credit: Foxconn

Top robot developers use Isaac robotics platform

NVIDIA claimed that top robot developers are using the Isaac robotics platform to create AI-enabled autonomous devices and robots. They included more than a dozen world leaders in the robotics industry, including BYD Electronics, Siemens, Teradyne Robotics, and Intrinsic.

These users are adding NVIDIA Isaac-accelerated libraries, physically-based simulation, and AI models to their software frameworks and robot models. This can make factories, warehouses, and distribution centers more efficient and safer for people who work there, said NVIDIA. It added that the robots can help people with repetitive or very precise tasks.

“The era of robotics has arrived. Everything that moves will one day be autonomous,” said Huang. “We are working to accelerate generative physical AI by advancing the NVIDIA robotics stack, including Omniverse for simulation applications, Project GR00T humanoid foundation models, and the Jetson Thor robotics computer.”

Siemens, a worldwide leader in industrial automation, uses NVIDIA Isaac Sim for its software-in-the-loop capabilities. The company said Isaac technologies speed its development and testing of new robotics skills like SIMATIC Robot PickAI (PRO) and SIMATIC Robot Pack AI.

According to Siemens, the industrial robots can now independently and successfully pick and pack arbitrary goods without human training by using cognitive AI vision software.

“AI-powered robots will accelerate the digital transformation of industry and take over repetitive tasks that were previously impossible to automate so we can unlock human potential for more creative and valuable work,” said Roland Busch, president and CEO at Siemens AG.

Siemens said it also brings vision AI to robots from KUKA, Techman Robot, Universal Robots, and Yaskawa by seamlessly integrating with automation solutions and making it easy to use on an NVIDIA-powered Siemens industrial PC foundation.

Foxconn virtual factory digital twin built using AI, NVIDIA Omniverse, NVIDIA Isaac and NVIDIA Metropolis. | Credit: Foxconn

Intrinsic using Isaac Manipulator to simulate robot gripping

Alphabet software and AI robotics subsidiary Intrinsic, which purchased Open Source Robotics Corporation in late 2022, tested Isaac Manipulator on its robot-agnostic software platform. With Manipulator, Intrinsic showed that a scalable, universal robotic-grasping talent can function across grippers, settings, and objects.

Solomon, Techman Robot, Vention and Yaskawa are among the companies using Isaac Manipulator for building AI-based robotic arms. With partners ADLINK, Advantech, and ONYX, NVIDIA said AI Enterprise on the IGX platform offers edge AI systems meeting strict regulatory standards, essential for medical technology and other industries.

“We couldn’t have found a better collaborator in NVIDIA, who are helping to pave the way for foundation models to have a profound impact on industrial robotics,” stated Wendy Tan White, CEO of Intrinsic. “As our teams work together on integrating NVIDIA Isaac and Intrinsic’s platform, the potential value we can unlock for millions of developers and businesses is immense.”

Over 100 companies are adopting NVIDIA Isaac Sim to simulate, test and validate robotics applications, including Hexagon, Husqvarna Group, and MathWorks. Humanoid robot developers Agility Robotics, Boston Dynamics, Figure AI, Fourier Intelligence, and Sanctuary AI are adopting Isaac Lab.

In addition, NVIDIA noted that robotics developers such as Moon Surgical and the SETI Institute are using NVIDIA Holoscan on the updated IGX Orin platform for sensor processing and deploying AI and high-performance computing for flexible sensor integration and real-time insights.

Hi,

I am Samuel Dubin, IP manager of eCential Robotics.

The image you use to illustrate Virtual Incision robot in your article is not Virtual Incision robot image but eCential Robotics one.

Please, correct this mistake to avoid misinterpretation.

Best regards.

Samuel, we’ve updated the credit for that image. Thank you for the correction.