|

Listen to this article

|

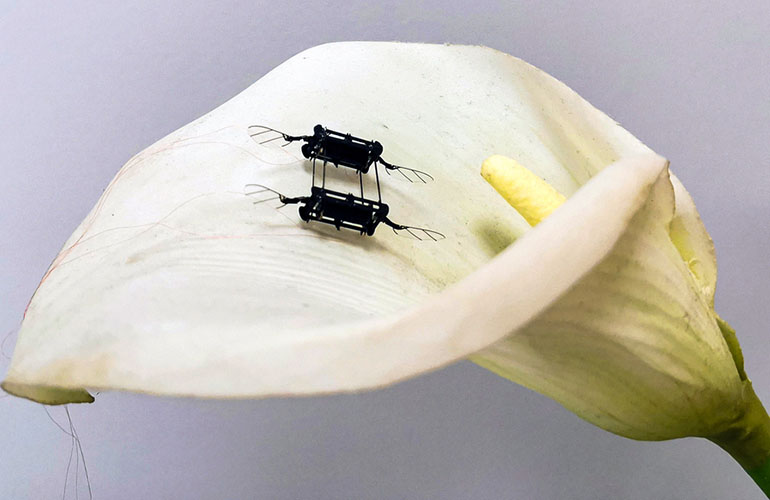

These nano drones use soft actuators to fly through the air. | Source: MIT

Researchers at MIT have created a tiny robot, weighing less than 1 gram, that can zip around with insect-like agility and resilience. The research team isn’t the first to take on the challenge of making tiny flying robots. After all, they do have a number of real-world applications such as pollinating a field of crops or searching for survivors in disaster areas.

Typically, these kinds of robots are made with rigid actuators built from piezoelectric ceramic materials. The rigid materials help the robot to fly, but they also make it fragile. These types of robots are unlikely to survive the number of collisions it would face in the real world.

Soft actuators can be much more resilient than rigid ones, but they present a different problem for tiny robots. They require higher voltages than rigid actuators, and more voltage means bigger power electronics that the robot isn’t capable of lifting.

Kevin Chen, an assistant professor in the department of electrical engineering and computer science, and senior author of the study, worked with his team to create a new fabrication technique for soft actuators. The produced actuators operate with 75% lower voltage than current versions and can carry 80% more payload.

The team’s rectangular robot has four sets of wings, each driven by an actuator, that beat nearly 500 times per second. The actuators work like artificial muscles, and are made up of layers of elastomer placed between two very thin electrodes and rolled into a squishy cylinder.

The wings flap by applying voltage to the actuator, which makes the electrodes squeeze the elastomer.

One defect after another

One challenge the team faced was creating more surface area for the robot. The actuator requires less voltage with more surface area, so the team tried to build as many thin layers of elastomer and electrode as possible. However, the thinner the elastomer layers are, the more unstable the robot is.

The team was able to create layers that were only 10 micrometers in thickness by rethinking the fabrication process. For example, during the spin coating process, where an elastomer is poured onto a flat surface and rapidly rotated to make thinner layers of film, the team had to contend with tiny air bubbles that the spinning process created.

“In this process, air comes back into the elastomer and creates a lot of microscopic air bubbles. The diameter of these air bubbles is barely 1 micrometer, so previously we just sort of ignored them,” Chen said. “But when you get thinner and thinner layers, the effect of the air bubbles becomes stronger and stronger. That is traditionally why people haven’t been able to make these very thin layers.”

To get around this, the team performed the vacuuming process after spin coating, before the elastomer had a chance to dry, and then baking the actuator to dry it. By solving this problem, the team was able to increase the power output of the actuator by more than 300% as well as increase the lifespan of the actuator.

Baking the elastomer layers also helped to reduce the curing time of the actuator.

The artificial muscles improve the robot’s payload and allow it to achieve better hovering performance. | Photo Credit: Kevin Chen

“The first time I asked my student to make a multilayer actuator, once he got to 12 layers, he had to wait two days for it to cure. That is totally not sustainable, especially if you want to scale up to more layers,” Chen said.

The team also ran into issues with the thin electrodes in the actuator. The electrodes are made up of carbon nanotubes that are about 1/50,000 the diameter of a human hair. The more nanotubes the actuator has the higher the actuator’s power output is.

The nanotubes, however, have sharp ends that could pierce the elastomer, so the team had to find the optimal number of nanotubes.

“Two years ago, we created the most power-dense actuator and it could barely fly. We started to wonder, can soft robots ever compete with rigid robots? We observed one defect after another, so we kept working and we solved one fabrication problem after another, and now the soft actuator’s performance is catching up,” Chen said. “They are even a little bit better than the state-of-the-art rigid ones. And there are still a number of fabrication processes in material science that we don’t understand. So, I am very excited to continue to reduce actuation voltage.”

The resulting robot could hover for 20 seconds. According to Chen, this is the longest ever recorded by a sub-gram robot. It also had a longer lifespan than other actuators, lasting more than two million cycles.

The team plans to continue testing fabrication techniques in a clean room where it won’t have to contend with dust in the air when creating the actuator layers. Chen hopes to make the layers as thin as 1 micrometer.

Tell Us What You Think!