|

Listen to this article

|

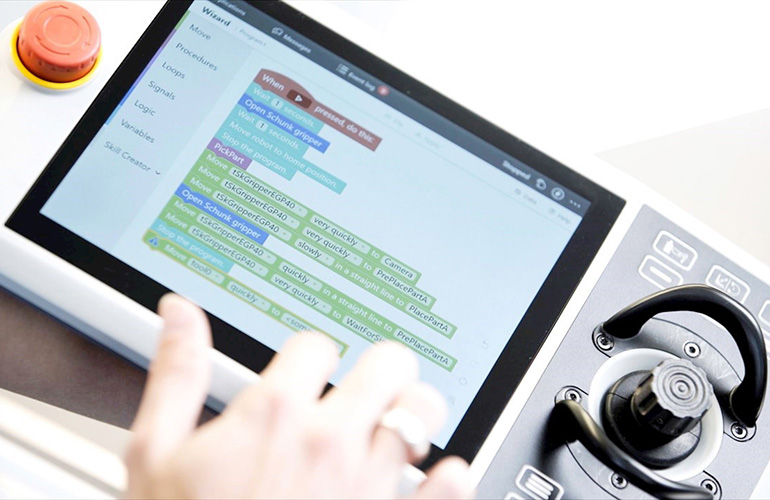

A look at ABB’s Skill Creator inside its Wizard Easy Programming software. | Source: ABB

ABB Robotics has expanded its free Wizard Easy Programming software to include its six-axis industrial robots that use an OmniCore controller, which already works with its collaborative robots. The Zurich, Switzerland-based company claimed that its system lowers barriers to automation for new users and offers ecosystem partners and integrators a tool to support their customers.

Wizard Easy Programming intended to speed setup

Released in 2020, ABB’s Wizard Easy Programming uses a graphical, no-code, drag-and-drop programming approach. The company said it designed the software to help both first-time and expert robot users to develop applications in just minutes.

Without Wizard Easy Programming, this task can take a week of training and another week of development, noted ABB.

Since its release, Wizard Easy Programming has been adopted in various applications using ABB’s cobot portfolio, which includes the Yumi, SWIFTI, and GoFa product families.

Wizard Easy Programming provides operational flexibility in addition to helping operators with no prior training to develop cobot applications, said ABB. The company asserted that the software allows users to modify existing programs and pre-programmed blocks through an intuitive graphical interface. Users can modify behaviors ranging from robot movements to signal instructions and force control.

“Addressing industry challenges and opportunities is essential to sustain and accelerate the worldwide adoption of robotics automation,” Marc Segura, president of ABB Robotics, said in a release. “By extending Wizard Easy Programming to our six-axis industrial robots, ABB Robotics is responding to the scarcity of skilled labor and rising manufacturer demand for simple and easy-to-use robot programming software for their robot fleets.”

Skill Creator helps users and developers, says ABB

With Wizard Easy Programming, ABB aims to cater to both novice and experienced users. The program comes with Skill Creator, a tool to help system integrators and other expert users efficiently create customized, application-specific Wizard blocks for use with their customers.

The company claimed that Skill Creator can simplify the creation of highly specific tasks such as machine tending and welding. It is also suitable for complex applications like medical inspections, it said.

ABB added that ecosystem partners developing accessories such as grippers, feeders, and cameras will gain access to a digital tool to share product-specific functionalities. With Wizard Easy Programming’s extended scope, partners will have this access regardless of the type of robot their technology will be deployed on, the company said.

Wizard Easy Programming software will come preinstalled on all ABB cobots and new six-axis industrial robots using its OmniCore robot controller family. OmniCore delivers an average of 20% energy savings, offers built-in digital connectivity, and more than 1,000 scalable functions, according to ABB.

Earlier this month, SUS Corp., a Japanese supplier of aluminum frames and die-cast aluminum components for the automotive industry, deployed a series of ABB’s YuMi dual-armed cobots. SUS said ABB’s robots are helping it to reshore its production and address challenges presented by workforce shortages.

In September, ABB announced that it will invest $280 million in a new robotics campus in Västerås, Sweden, that will serve as the hub for ABB Robotics’ offerings in Europe. The company said it plans to start construction on the new campus in the first quarter of 2024 and to complete it by the end of 2026.

ABB said the new facility will increase its manufacturing capacity for collaborative and industrial robot arms by 50% and enable it to better serve the European market.

Tell Us What You Think!