|

Listen to this article

|

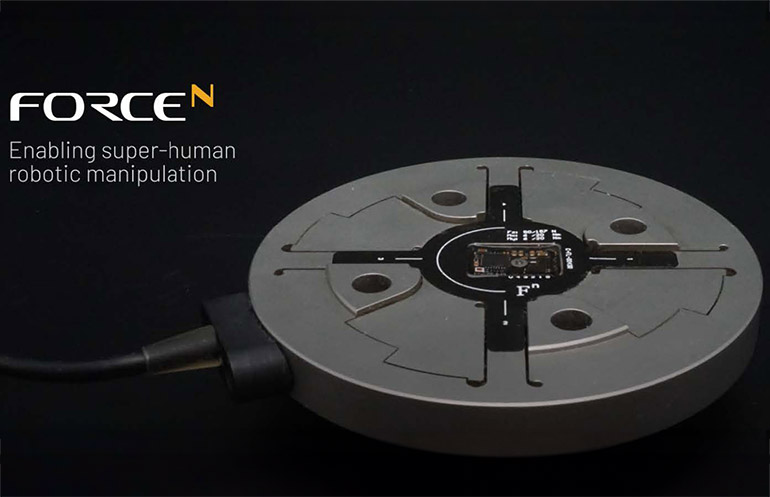

Forcen says its technology will help robotic manipulation advance as vision has. Source: Forcen

Forcen last week said it has closed a funding round of CAD $8.35 million ($6.1 million U.S.). The Toronto-based company plans to use the investment to scale up production to support more customers and to continue developing its force/torque sensing technology and edge intelligence.

“We’ve been focused on delivering custom solutions showcasing our world-first technology with world-class quality … and we’re excited for our customers to announce the robots they’ve been working on with our technology,” stated Robert Brooks, founder and CEO of Forcen. “Providing custom solutions has limited the number of customers we take on, but now we’re working to change that.”

Founded in 2015, Forcen said its goal is to enable businesses to easily deploy “(super)human” robotic manipulation in complex and unstructured applications. The company added that its technology is already moving into production with customers in surgical, logistics, humanoid, and space robotics.

Forcen offers two paths to robot manipulation

Forcen said its new customizable offering and off-the-shelf development kits will accelerate development for current customers and help new ones adopt its technology.

The rapidly customizable offering will use generative design and standard subassemblies, noted the company. This will allow customers to select the size, sensing range/sensitivity, overload protection, mounting bolt pattern, and connector type/location.

By fulfilling orders in as little as four to six weeks, Forcen claimed that it can replace the traditional lengthy catalog of sensors, so customers can get exactly what they need for their unique applications.

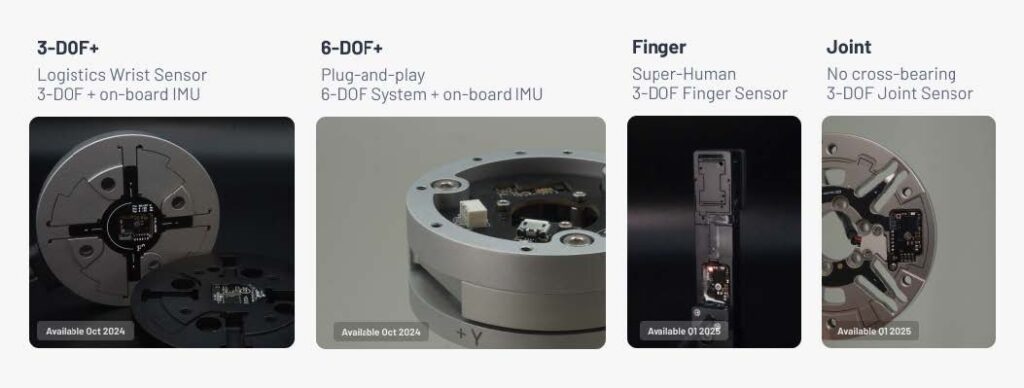

The company will launch its off-the-shelf development kits later this year. They will cover three degree-of-freedom (DoF) and 6 DoF force/torque sensors, as well as Forcen’s cross-roller, bearing-free 3 DoF joint torque sensor and 3 DoF gripper finger.

Off-the-shelf development kits will support different degrees of freedom. Source: Forcen

Force/torque sensors designed for complex applications

Complex and less-structured robotics applications are challenging for conventional force/torque sensing technologies because of the risk of repeated impact/overload, wide temperature ranges/changes, and extreme constraints on size and weight, explained Forcen. These applications are becoming increasingly common in surgical, logistics, agricultural/food, and underwater robotics.

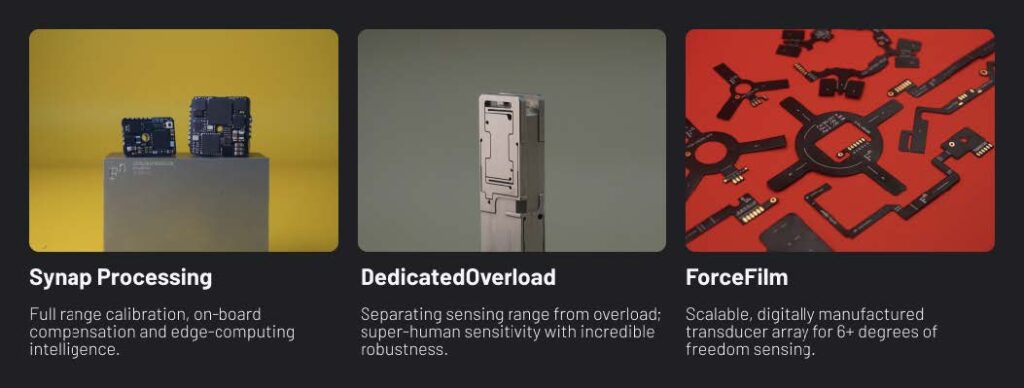

Forcen added that its “full-stack” sensing systems are designed for such applications using three core proprietary technologies:

- ForceFilm — A monolithic thin-film transducer enabling sensing systems that are lighter, thinner, more stable across both drift and temperature, the company said. It is especially scalable for multi-dimensional sensing, Forcen said.

- Dedicated Overload — A protection structure that acts as a 6 DoF hard stop. The company said it allows sensitivity and overload protection to be designed separately and enables durable use of the overload structure for thousands of overload events while still achieving millions of sensing cycles.

- Synap — Forcen’s onboard edge intelligence comes factory compensated/calibrated and can connect to any standard digital bus (USB, CAN, Ethernet, EtherCAT). This can “create a full-stack force/torque sensing solution that is truly plug-and-play with a maintenance/calibration-free operation.

New offerings include features to support demanding robotics applications. Source: Forcen

Learn about Forcen at the Robotics Summit

Brightspark Ventures and BDC Capital’s Deep Tech Venture Fund co-led Forcen’s funding round, with participation from Garage Capital and MaRS IAF, as well as returning investors including EmergingVC.

“Robotic vision has undergone a revolution over the past decade and is continuing to accelerate with new AI approaches,” said Mark Skapinker, co-founder and partner at Brightspark Ventures. “We expect robotic manipulation to quickly follow in the footsteps of robotic vision and Forcen’s technology to be a key enabler of ubiquitous human-level robotic manipulation.”

Forcen is returning to the Robotics Summit & Expo this week. It will have live demonstrations of its latest technology in Booth 113 at the Boston Convention and Exhibition Center.

CEO Brooks will be talking on May 1 at 4:15 p.m. EDT about “Designing (Super)Human-Level Haptic Sensing for Surgical Robotics.” Registration is now open for the event, which is co-located with DeviceTalks Boston and the Digital Transformation Forum.

Tell Us What You Think!