|

Listen to this article

|

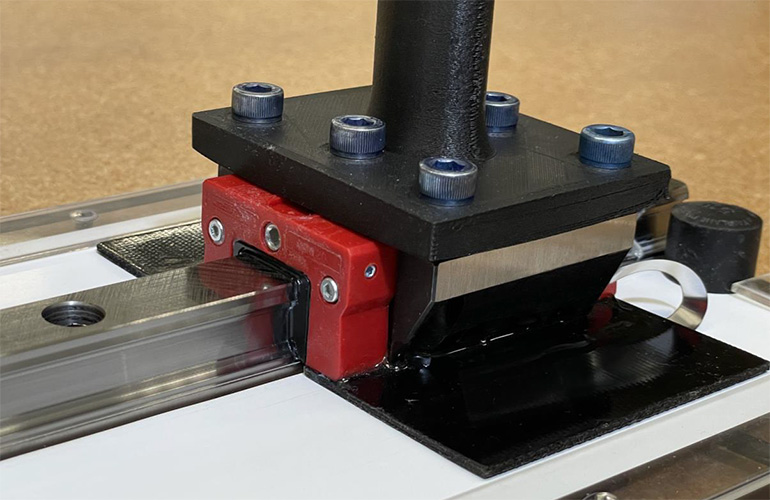

The new linear brake solution uses electrical fields to hold the axis. | Credit: ESTAT

ESTAT Actuation engineers and manufactures electronic brakes and clutches that use the physics of electric fields to deliver a braking or clutching interaction when powered on. The company spun out from Carnegie Mellon University in 2019 and introduced its first innovation with a rotary joint clutch/brake product, useful for robotics applications. Now the company is expanding its product line to offer what it describes as an electroadhesive braking solution for linear motion axes.

Electroadhesion appears to work like magic

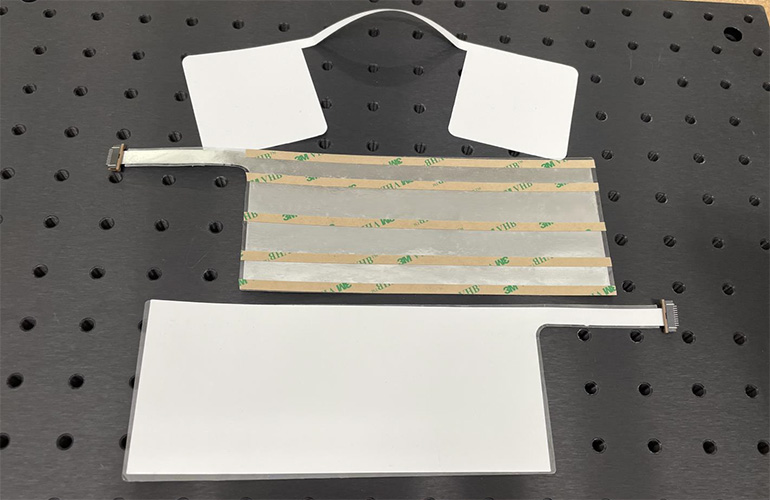

ESTAT clutches utilize the phenomenon of static electricity to adhere and detach surfaces. You can generate static voltage fields using little energy and thin components, making them an advantageous choice for actuator design due to their lightweight and efficient nature.

The new Linear Clutch from ESTAT offers the adhesion function along a linear path, rather than the rotational path of its first product offering. In its off-the-shelf configuration, the Linear Clutch is capable of transmitting up to 100 N (approx. 25 lbs) in tension while consuming just milliwatts of power.

Note: The Linear Clutch is designed to support tensile loads only, however, the company is also exploring compressive loads use cases.

ESTAT clutches are load-bearing capacitors. When voltage is applied to the clutch webs, positive charges and negative charges build up on either side of the clutch. This leads to the formation of adhesion between the clutch webs, which hinders any further expansion of the clutch.

When not in use, the clutch may move smoothly with very little resistance from tensioners. ESTAT clutches, functioning as capacitors, only need a small amount of maintenance current (< 10 µA) to stay engaged. The clutch disengages when the electrical potential is eliminated.

The new ESTAT linear brake leverages the same physics as its rotary brake, offering a low energy option to mechanical brakes for linear axis. | Credit: ESTAT

Kirby Witte, ESTAT VP of Engineering, will present a live presentation and demonstration of the new linear brake at Automate on Thursday, May 9 at 12:45 PM (Eastern) on the Innovation Stage.

Tell Us What You Think!