|

Listen to this article

|

The range of manipulation tasks that robots can carry out is growing, according to FAULHABER. It includes everything from grasping and holding to clamping and screwing, as well as foaming and welding, said the German company.

When it comes to standardized mass production, specialized robots can perform the same tasks day and night. But many processes require flexibility, such as when it comes to batch size 1. This is also important to save on investment costs. The greater the range of tasks that a robot can carry out, the better, FAULHABER said in a blog post.

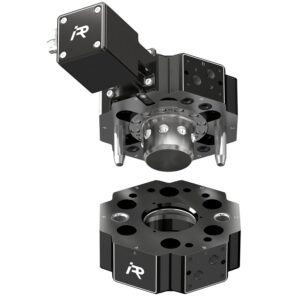

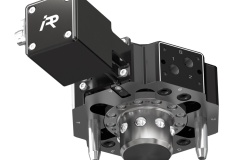

Tool changer with brushless flat motor. Source: FAULHABER

Intelligent Peripherals for Robots (IPR) aims to solve these problem with its TKX tool changer. Mounted to the end of a robot arm, it can remove a variety of tools from a rack, according to IPR.

For example, TKX enables the robot to first grip and position a workpiece, then process it with tools, and finally check and document the quality with a contour sensor or a camera. For this, the adapter needs suitable feed-throughs for the corresponding tool functions.

The TKX series provides options, as well as several lateral screw-on surfaces for additional modules. However, the main task of the tool changer is to securely lock the tool when it is picked up and to quickly and consistently release the lock again when it is set down after use.

Applications determine chose of pneumatic or electric

Traditionally, many industrial applications use pneumatic power transmissions, said FAULHABER. Compressed-air technology has proven itself over decades, and it is suitable for handling very heavy objects, the company noted. But a pneumatic system requires compressors, lines, and its own control system with numerous mechanical components – a considerable investment in new systems.

In industries with increased demands on cleanliness and hygiene, such as microelectronics or food, pneumatics are out of the question because of the unavoidable emission of compressed air. And pneumatics are an absolute no-go in clean rooms. Eppingen, Germany-based IPR said it has seen a significant trend towards the use of electric drives instead of pneumatic ones.

“In addition to the hygienic safety, electric motors are much more flexible in use,” said the company. “Unlike compressed air connections, power sockets are available almost anywhere.”

“In newly built industrial plants, pneumatic systems are generally no longer installed,” IPR added. “For cobots and smaller robots as well as for decentralized locations, the electric version is almost always the better solution.”

The fact that the electric drive is a real alternative to pneumatics today also has something to do with motor technology, explained Roman Batz, development engineer at IPR.

“Great strides have been made in recent years,” he said. “For our applications, we basically need a lot of power with very small dimensions. FAULHABER offers motors that can easily hold their own compared to pneumatic drives.”

FAULHABER motors to open, close, and hold

Holding up is also meant quite literally here. Currently, the most powerful electric model in the TKX series, the TKE 300, is suitable for handling objects weighing up to 300 kg (661.3 lb.), said IPR.

In metal processing, robots can handle heavy loads such as cast blocks or large forged parts. The pulling force of their overall mass then acts upon the locking ring in the TKX changer.

The torque supplied by the motor in standby mode would be enough for safe holding. But to ensure particularly reliable fixation, IPR has also installed self-retaining kinematics, which were developed in-house.

“A brushless motor from the FAULHABER BXT family provides the driving force for opening, closing, and holding,” FAULHABER said. “With its external rotor technology, it achieves a ratio of torque to weight and volume that is unrivaled on the market. This power density is one of the prerequisites for the unique selling point of the new product family from IPR.”

“The TKX series are the first tool changers on the market that are available on the same platform with both pneumatic and electric drives – we also have a manual version in the product range,” Batz said. “This means that the entire range of accessories can be used with all drive types without retooling. And switching to electric operation is also quite easy. This opens up new possibilities for robotic automation.”

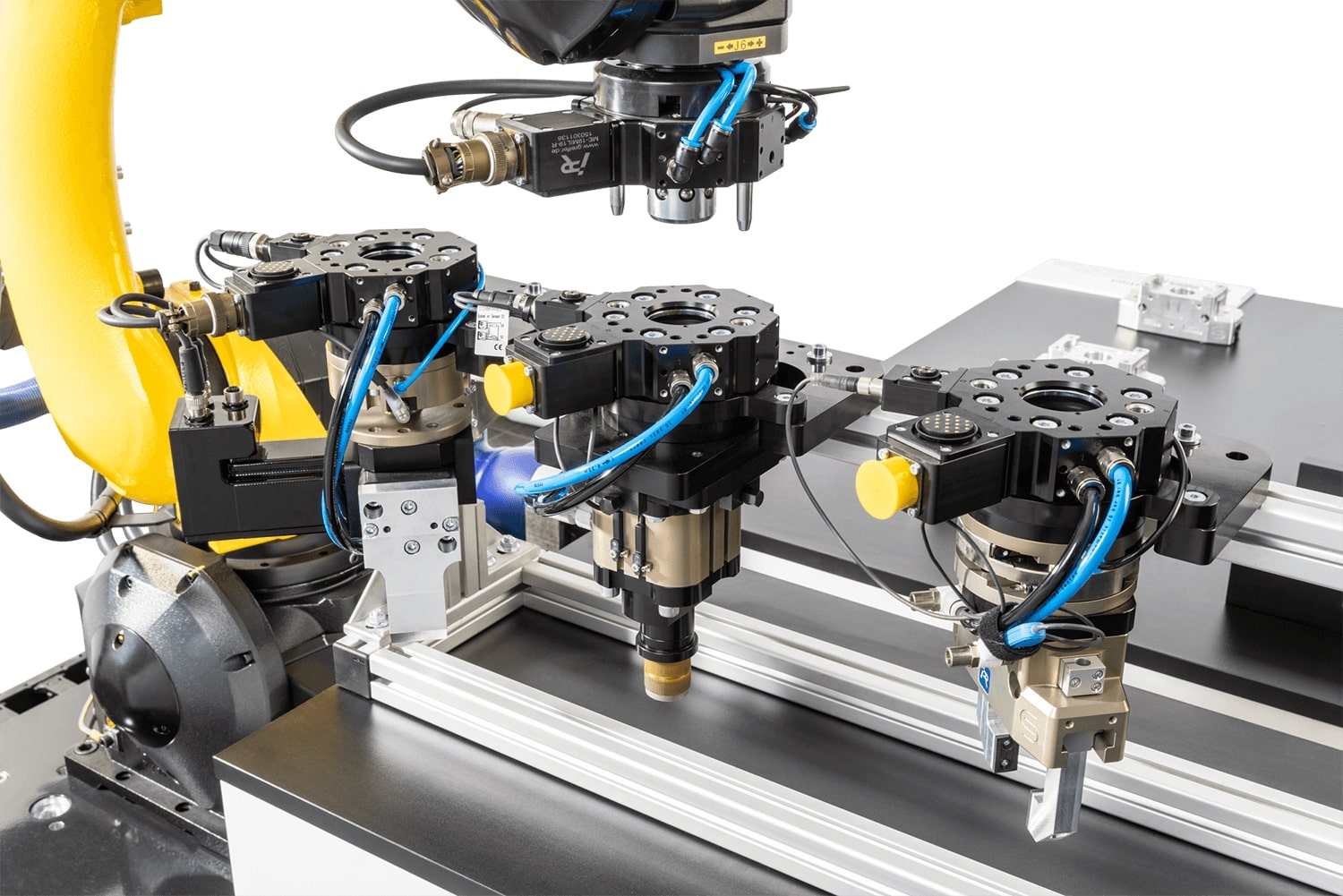

IPR’s TKX tool changer includes an electric FAULHABER motor. Source: FAULHABER

Components designed to be reliable, easy to combine

The TKE changers will be available in seven sizes for handling workpieces from 3 to 300 kg (6.6 to 661.3 lb.), according to IPR. The electric variant of the product family thus covers a wide range of applications, from lightweight robots to stationary applications. The dimensions of the BXT motors used are adapted to the application.

“The range of sizes and the large selection of suitable gears for the optimum reduction in each case was an important criterion for us,” Batz said. “Robots should be able to achieve seven-digit cycle numbers without maintenance. So only a brushless motor with the highest possible processing quality can be used. It should be easy to control and manage without additional control – the integrated speed controller takes care of that. Last but not least, the components have to be able to withstand temperatures of up to +80°C.”

IPR procures all of its micromotors from FAULHABER. “We started working together many years ago, long before my time,” Batz said. In addition to the unique quality of the products, other aspects play an important role for him.

“It starts with the very simple design of motor-gear combinations on the FAULHABER website,” said Batz. “It takes just a few clicks to get a comprehensive overview. The technical details are very well documented, and when it comes to precisely calculating the finer points – efficiency, power consumption, temperature development over time, etc. — I always get the support I need.”

An example IPR workcell with the robotic tool changer. Source: FAULHABER

Editor’s note: This article was syndicated with permission from FAULHABER’s blog.

Tell Us What You Think!