|

Listen to this article

|

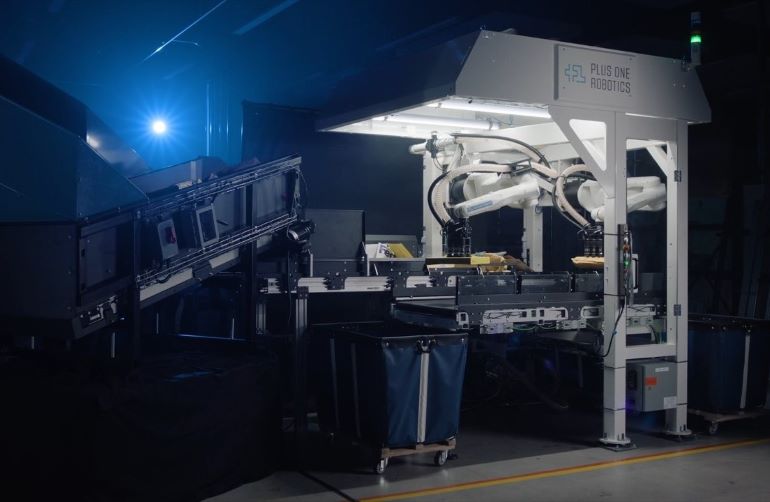

InductOne is designed to handle a wide range of parcels with high throughput. Source: Plus One Robotics

CHICAGO — As items pass through warehouses and other facilities, they are often handled as packages rather than as eaches. Plus One Robotics yesterday launched InductOne, a two-armed robot designed to optimize parcel singulation and induction in high-volume fulfillment and distribution centers.

“Parcel variability is a significant challenge of automation within the warehouse,” stated Erik Nieves, CEO of Plus One Robotics. “That’s why InductOne is equipped with our innovative individual cup control [ICC] gripper, which can precisely handle a wide range of parcel sizes and shapes.”

“But it’s not just about what InductOne picks, it’s also about what it doesn’t pick,” he added. “The system avoids picking non-conveyable items, allowing them to automatically convey to a designated exception path and preventing the robots from wasting precious cycles handling items which should not be inducted.”

“We’ve doubled down on parcel handling; we’re not an each picking company,” Nieves told The Robot Report. “Vision and grasping for materials handling is hard, and Plus One continues to focus on packaged goods, which spend most of their time as parcels and can be picked by vacuum grippers.”

InductOne engineered for ease of integration, efficiency

InductOne’s dual-arm design “significantly outperforms single-arm solutions,” claimed Plus One. “While a single-arm system typically tops out at around 1,600 picks per hour, the coordinated motion of InductOne’s two arms can achieve sustained pick rates of 2,200 to 2,300 per hour. InductOne’s peak rate maxes out at a rate of 3,300 picks per hour, 10% faster than the leading competition.”

Plus One Robotics said its engineering team designed InductOne to be capable but as small as possible for easy integration into brownfield facilities and to minimize the need for costly site modifications.

“The engineering approach behind InductOne has been focused on efficiency and flexibility,” said Nieves. “We designed the system to be as compact and lightweight as possible, making it easier to deploy in limited spaces, including on existing mezzanines. The modular and configurable nature of InductOne also allows it to seamlessly integrate into a variety of fulfillment center layouts.”

InductOne includes the PickOne vision system, the Yonder remote supervision software, pick-and-place conveyors, integrated safety features, analytics, and training and ongoing support. The modular system is also offers configurable layouts for cross-belt or tray sorters.

It can handle parcels weighing up to 15 lb. (6.8 kg) and up to 27 in. (69 cm) in length, 19 in. (48 cm) in width, and 17 in. (43 cm) in height. InductOne supports boxes, clear and opaque polybags, shipping envelopes, and padded and paper mailers.

InductOne includes vision and grasping refined by millions of picks of experience. Source: Plus One Robotics

Plus One Robotics touts experience and trust

Founded in 2016 by computer vision and robotics industry experts, Plus One Robotics said it combines computer vision, artificial intelligence, and supervised autonomy to pick parcels for leading logistics and e-commerce organizations. The San Antonio, Texas-based company has offices in Boulder, Colo., and the Netherlands.

Plus One said it applied its experience from more than 1 billion picks to develop InductOne. The company said it has learned from handling over 1 million picks per day, and achieving the reliability required for such high-volume operations led to its new parcel-handling machine.

“ICC and InductOne are the culmination of our learnings from these picks,” said Nieves at Automate. “It’s not just vision but also grasping and conveyance. I push back against those who say, ‘Data, data, data,” because we also need to appreciate the things above and below our system. We’re applying our expertise to the problem, but we’re not trying to be an integrator or just a hardware maker.”

Nieves noted that the value of robotics-as-a-service (RaaS) models is not recurring payments but the option they give users to scale deployments up or down as needed.

“As Pitney Bowes’ Stephanie Cannon said in a panel, it’s important [for automation providers] to get to 70% confidence and then work with customers who trust that you’ll work with them to get the rest of the way,” he said. “Our relationships with FedEx and Home Depot for palletization and parcel handling are built on that trust.”

The line between automation and humanoid robotics is blurring.